OZONE

DESTRUCT UNIT SPECIFICATIONS

HA

- SERIES

MECHANICAL

| MODEL |

HA-58 |

HA-434 |

| |

|

|

| DIAMETER |

4”

X 0.083” tubing |

4”

X 0.083” tubing |

| BED

LENGTH |

26” |

30” |

| OVERALL

LENGTH |

32” |

36” |

| INLET

CONNECTION |

_”

welded |

_”

welded |

| OUTLET

CONNECTION |

_”

welded |

_”

welded |

| MATL

OF CONSTRUCTION |

316L

SS ep |

316L

SS ep |

| BED

VOLUME |

0.175

cu. ft. |

0.211

cu. ft. |

| CATALYST

TYPE |

Carulite

200 |

Carulite

200 |

| CATALYST

WEIGHT |

11.3

pounds |

13.7

pounds |

PROCESS

SPECIFICATIONS

| FLOW

RATE* |

20

slpm |

30

slpm |

| |

|

|

| SUPERFICIAL

VELOCITY |

0.15 ft/sec

|

0.21 ft/sec |

| INLET CONCENTRATION

* |

12.5 wt

% |

12.5 wt

% |

| OUTLET

CONCENTRATION |

<0.01

ppm |

<0.01

ppm |

| MAXIMUM

TEMPERATURE |

250 C |

250 C |

| NORMAL

OPERATING TEMP |

150 C |

150 C |

INSTRUCTIONS FOR THE HA SERIES OZONE DESTRUCT UNIT

INTRODUCTION

The HA series ozone destruct unit utilizes a thermal-catalytic method

to remove excess ozone. The catalyst is a transition metal manganese

dioxide-copper oxide material. It is not consumed by the ozone and

acts as a true catalyst. The material is non-hazardous and can be

removed to a Class 1 landfill. The conversion of ozone to oxygen

is an exothermic reaction and the combination of catalyst and heat

generated in the reaction is a very efficient method of ozone destruction.

External temperatures may reach as high as 150 C and steps must

be taken to prevent accidental contact with an operator.

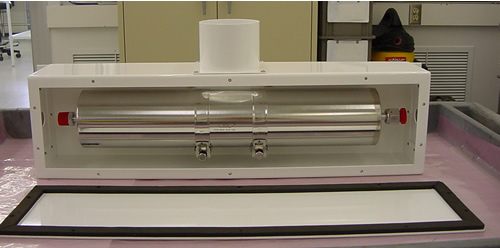

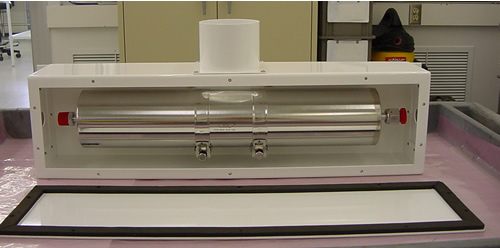

HA-434

General Layout

Download HA-434 General Layout PDF

Download HA-434 Performance PDF

INSTALLATION

The HA unit is typically mounted vertically and ozone gas flows

from bottom to top of the unit. An arrow etched on the unit shows

the flow direction. The unit must be supported securely to a wall

or strut, either with pipe straps or from below the catalyst canister.

The latter is the recommended method. The exit is out the top of

the unit and must not be obstructed. The exit of the HA unit can

be left open to atmosphere or piped to an outside area or scrubber,

away from personnel. The HA is designed to have a 0.00 ppm ozone

concentration at its exit. Be sure that the ozone flow rate does

not exceed the specifications for the unit. If the flow rate is

too high, complete ozone destruction will not take place. Performance

curves for the HA units are available.

The unit will also work if mounted horizontally, but this is not

recommended. It is possible that some ozone gas could by-pass the

catalyst.

The standard HA unit is supplied with welded end connections and

is welded into the operating line to prevent leaks. However, the

unit is also available with compression and VCR fittings. A refillable

option is also available.

Pressure drop of each unit is designed to be less than 1 inch water

column.

OPERATION

Before using the HA ozone destruct unit, be sure to check for leaks

in the system. The unit is helium leak checked at the factory, but

connections should be checked after installation. At that time,

ozone offgas can be introduced into the destruct unit. On cold start-up,

a break through of ozone may take place. Typically, this is on the

order of 0.05 – 0.010 ppm ozone or less. This break though

should last for less than one minute, until the unit heats as result

of the heat of reaction. Check again for leaks and make sure that

no ozone can be detected in the room. A room monitor is still recommended,

even when the ozone destruct unit is used.

PLEASE DO NOT TOUCH THE UNIT WHILE IN OPERATION!!!

LIFE OF THE CATALYST

The manganese dioxide-copper oxide is a true catalyst and is not

consumed. However, certain contaminants can reduce the reactivity

of the unit. These contaminants include hydrocarbons, moisture,

and particles. Of particular interest in semiconductor applications,

NOx (oxides of nitrogen) may reduce the reactivity of the unit over

time. The NOx is a by-product of some high concentration ozone generators,

particularly if the generator is doped with nitrogen, typically

0.5-2.0 % by volume. The life of the catalyst will depend on the

doping rate and the number of hours the unit is operated. A typical

lifetime for a unit in these conditions is 1-5 years.

|

HA-434 installed in a Gas

Box |

| |

FOR MORE INFORMATION CONTACT:

Cindy Slezak

OzoneDestructs.com

510-758-5570

800-557-5393

510-758-5571 FAX

cindy@ozone-engineering.com

|